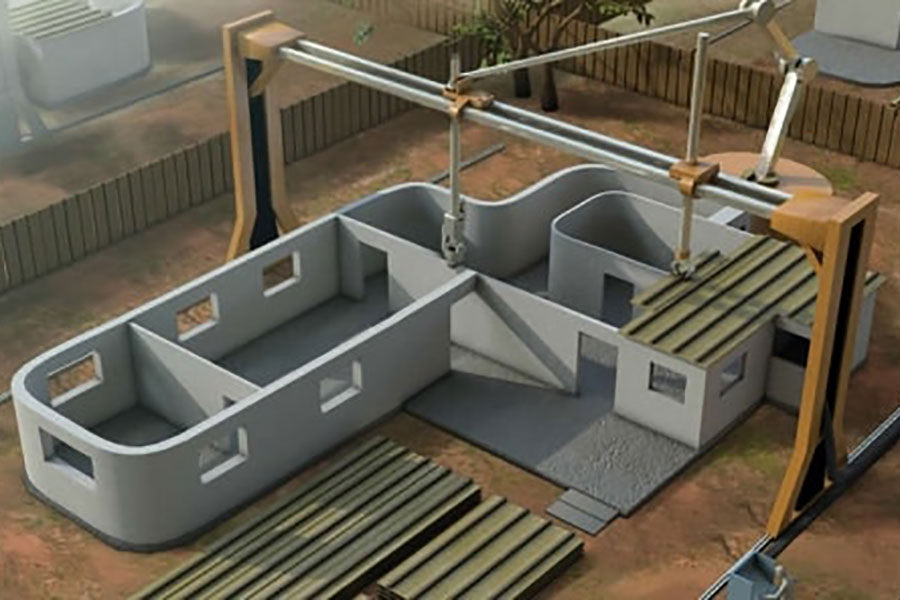

The construction of 3D-printed buildings, which has long been a fantasy, is gradually becoming a reality. The University of Southern California is currently testing a giant 3D printer used to build an entire house within 24 hours. The giant robot, designed by Professor Khoshnevis Behrokh, consists of a computer-controlled crane that projects concrete-like material to form a building's wall. This technology, known as Contour Crafting, could revolutionize the construction industry.

How does Contour Crafting work?

The contour crafting system is a robot that automates manual tools. They are handled by a robotic crane that builds three-dimensional objects. The jet pours concrete layers to create cavity walls filled with concrete. Construction workers then step in to lay the doors and windows.

This solution combines both design and production. Entire neighborhoods could be constructed with the technology, setting new records in completion time, cost, security, and architectural flexibility. The contour crafting solution also produces much stronger structures than traditional construction methods.

Will all buildings look alike?

One of the concerns regarding constructions built with this method is that they could all look alike. The systematic duplication of suburban buildings in the 1950s was widely criticized, although it allowed millions of people to live in good-quality housing. Will robots also be reproducing a myriad of identical housing units?

A simple answer is no. According to the computer program, buildings created with 3D technology can vary in form and height. Constructions will not have to look like a series of mass-produced homes. On the contrary, their architecture can be far more creative, as the 3D printer's jet allows for curved walls and other original architectural shapes without the risk of additional costs.

Will the technology allow for affordable homes?

Contour Crafting could cut home construction prices, allowing millions of poorly-housed people to own their property. Close to a billion people live in slum-like conditions, and these areas are breeding grounds for diseases. The recurring problem with conventional construction is that it is slow, laborious, and consequently inefficient for these populations. The Contour Crafting system would create an excellent shelter for people living below the poverty line, and it could additionally be used in disaster-stricken areas to build emergency housing.

What will happen to construction workers?

The implications for construction workers are, of course, a significant concern. Unlike other industries, construction has, up until now, largely escaped automation. It remains a solid source of labor worldwide and plays a vital role in the fight against unemployment.

The contour crafting process could lead to these people's dismissal and raises whether this system will do more harm than good.

Yet, it is essential to note that construction is risky, and the Bureau of Labor Statistics reports roughly 150,000 construction site accident injuries each year. While 3D printing technology will most likely provoke layoffs amongst the most injury-prone jobs in construction, it will also create new jobs in safer industry sectors.

What about the construction equipment industry?

A similar question can be raised concerning the many companies linked to manufacturing, distributing, and selling construction equipment. They concern brick-and-mortar businesses and the many construction equipment online platforms (MachineryZone, MachineryTrader, or IronPlanet). How will they cope with the change?

First, 3D printing will most likely be incorporated slowly and gradually into the industry, allowing suppliers to adapt and incorporate the technology into their business offerings. The world's leading brands, Volvo, Caterpillar, and Komatsu, have already announced using 3D printing technology to test prototypes.

Traditional construction equipment will also still be needed, and the difference will be that machines will be driven automatically. Instead of men in orange helmets and jackets, construction sites will be swarming with drones, robotic bulldozers, and giant 3D printers.

When will we see the first robots?

Hua Shang Tengda had already built the first 3D-printed house in China only 45 days earlier in 2016. Contour Crafting was voted one of the 25 best inventions of 2006 by the National Inventors Hall of Fame, but the process is still in the testing phase, and the first printers should be available within the next few years.

NASA and the Cal-Earth Institute fund the current research. The future development of Contour Crafting will concern the construction of modern city buildings and structures on the moon. They include landing pads, roads, shade walls, and other structural elements to evaluate the possibility of applying Contour Crafting technology in extraterrestrial environments.

Image source: Contour Crafting